Our company participated in the International Packaging Exhibition INTERPACK in Dusseldorf, Germany from May 4th to 10th, 2023. We welcome friends from the packaging industry to come and guide us!

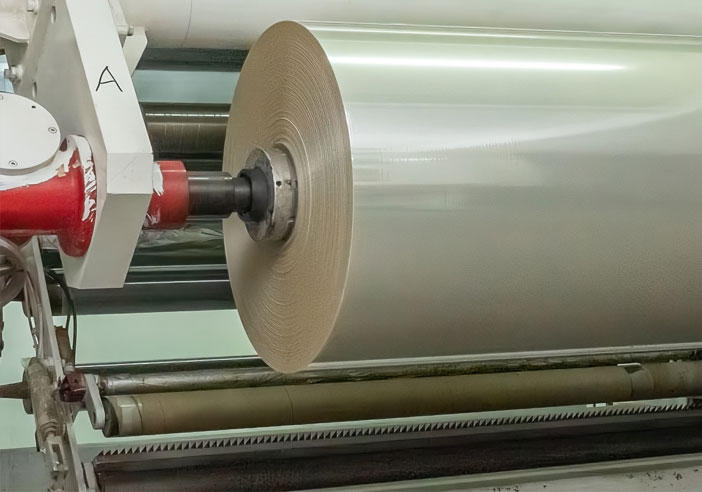

Zhejiang Yibai Packaging Materials Co., Ltd. is located in Quzhou, Zhejiang Province, located in the west of Zhejiang, Qiantang River upstream, south Fujian, west West, north Anhui, and Hangzhou, Jinhua, Lishui city in Zhejiang Province. It is the transportation hub and the political, economic and cultural center of western Zhejiang, known as the thoroughfare of four provinces. Founded in November 2010, the company is located in Kecheng District, Quzhou City, Zhejiang Province, covering an area of more than 40 mu. It has four leading professional PVDC coating production lines in China, with an annual production capacity of more than 10,000 tons. Products include high barrier PVDC coated film, PVA(PVOH) coated film, acrylic coated film, etc. PVDC coated film series is the current pla

Learn moreDeepening the field

Scientific research technology

Annual production volume

cover an area

Responsible for products and satisfying customers

Our service

Years of professional technology, focusing on packaging production, improving equipment quality, reducing equipment costs, and significantly reducing operating expenses

Immediately consult

Multiple customer experiences have proven that they maintain a high praise rate for most enterprises and have rich experience in papermaking and project cases.

Immediately consult

Excellent quality, more durable, richer, stronger adaptability, deeply trusted and praised by customers, improving market share and competitiveness.

Immediately consult

We are committed to creating a one-stop service system for papermaking professionals, providing customers with high-quality pre-sales, in sales, and after-sales services 24/7.

Immediately consultThe characteristics of PVDC coating film are obtained by coating one or more layers of polyvinylidene chloride (PVDC) latex on various film materials. Its excellent barrier performance is mainly manifested in the ability to reduce oxygen transmission hundreds or thousands of times, thereby greatly improving shelf life, freshness, aroma retention, oil resistance, and so on. Use specialized equipment to apply one or more layers of polyvinylidene chloride (PVDC) latex on various film materials, resulting in high barrier performance films. PVDC latex can be coated and processed on various film substrates such as BOPP, BOPET, BOPA, CPE, CPP, PVC, VMPET, etc., to produce different types of K coating films. And it has the same printability and composite properties as ordinary thin films, and can also have double-sided heat sealing performance as needed. The application of K coating is extremely extensive, with food and drug packaging as its main application areas. Generally speaking, using K coating film reduces the amount of materials used in packaging compared to ordinary PE film, paper, aluminum foil, etc., thus achieving the goal of reducing packaging and waste sources.

PVA coated high barrier film

PVA coated high barrier film is a multi-layer structure film composed of materials with strong gas barrier properties and polyolefins with strong thermal stitching and water barrier properties. PVA coated high barrier film is made by coating nano layered silicate modified PVA onto polyethylene film, printing, and composite, with an oxygen resistance rate of less than 2cm3/(m2 · 24h · 0.1MPa).

Its barrier performance is not only significantly superior to EVOH five layer co extruded film, but also significantly reduces packaging costs. This not only ensures all quality requirements for aseptic packaging for the packaged goods, but also significantly reduces the cost of aseptic packaging for food processing enterprises, solving the technical bottleneck of poor barrier performance of three-layer polyethylene co extruded packaging film. It can be used for packaging beverages, fruit juice, milk, soy sauce vinegar, etc.

Acrylic coated film

The biggest advantage of acrylic coating is its ability to heat seal at low pressure, which means it can be sealed at a lower pressure, so as not to deform the internal paper box under pressure. According to the online understanding of coating, acrylic acid can also provide a heat sealing window of 50 degrees Celsius (the temperature difference between the starting sealing temperature and the shrinkage temperature). The smaller the window range, the easier it is for the film to contract due to heat. Conversely, it can make the packaging flat and fit the paper box.

Perfume and some cosmetics containing natural essence will gradually evaporate over time, or be polluted by the fragrance of other products on the shelf, so odor barrier films are required for such products. Both acrylic acid and PVDC coatings have excellent gas barrier properties.